Polyester Hot Melt Sewing Thread

Polyester Hot Melt Sewing Thread

Sample price(Please consult for large freight charges)

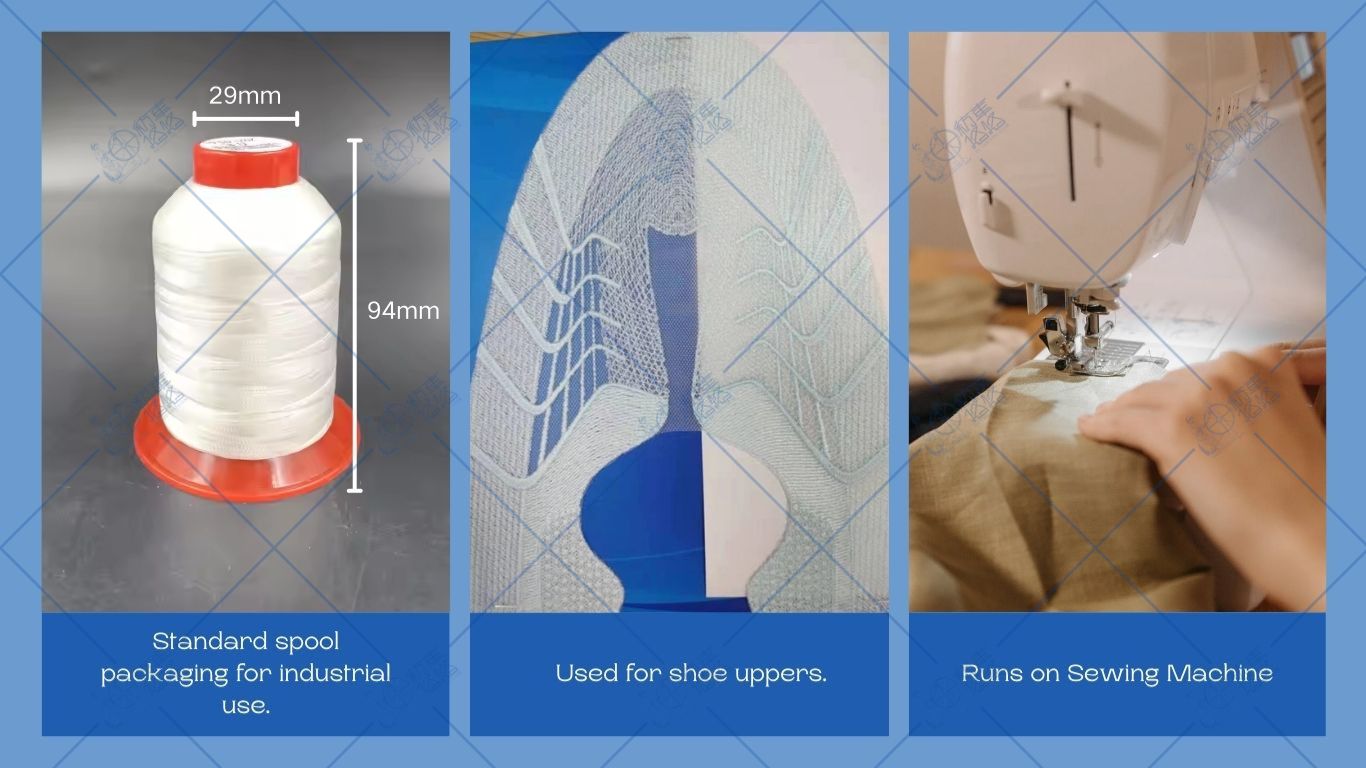

·Material: 100% Polyester

·Yarn count: 150D/3, 300D/3, etc.

·Melting Point: 130-150℃

·Packaging: 100g/cone.

✅Logo Customize

✅Packing Customize

✅Spec Customize

Description:

Polyester Hot Melt Sewing Thread from Dongguan Velve Thread Manufactury offers strong adhesion and clean finishes. Designed to melt and bond under heat, it’s perfect for seamless, glue-free stitching in fashion, footwear, and technical textiles.

Features:

1. Melting Temperature: The yarn melts at a lower temperature, typically between 130-150°C, making it ideal for thermal bonding processes.

2. Strong Bonding: When heat is applied, the yarn melts and forms strong bonds with other fibers, creating a cohesive and durable fabric structure.

3. Sew on standard machines, Improves production efficiency

4. Flexibility: Retains flexibility even after melting and bonding, ensuring comfort and usability in the final product.

5. Enhanced Durability: Provides added strength and stability to fabrics, making them more resistant to wear and tear.

Share

Material

PolyesterApplication

* Seamless garments* Footwear stitching

* Heat bonding applications

* Lingerie and underwear

* Outdoor apparel

* Industrial textiles

* Technical sportswear

* Upholstery sewing

Package

We offer you a variety of package sizes: 45*30*24cm , 48*39*23.5cm , 53*39*36cm and so on

Contact form

Collections

-

Luminous Series

Illuminate your designs with the Luminous Series from Dongguan Velve Thread Manufactury,...

-

Reflective Series

Dongguan Velve Thread Manufactury’s Reflective Series includes reflective yarn and reflective thread...

-

Conductive Series

Dongguan Velve Thread Manufactury is a leading supplier and manufacturer of premium...

Blog posts

View all-

How Functional Yarns in Outdoor Sports Equipmen...

Extreme outdoor adventures demand more than just skill—they require equipment built with intelligence and precision. Behind every high-performance jacket, climbing rope, or UV-blocking shirt lies a hidden force: functional yarn....

How Functional Yarns in Outdoor Sports Equipmen...

Extreme outdoor adventures demand more than just skill—they require equipment built with intelligence and precision. Behind every high-performance jacket, climbing rope, or UV-blocking shirt lies a hidden force: functional yarn....

-

From Yarn to Trendy Icons: The Hidden Textile C...

Pop Mart isn't just selling toys—it's reshaping pop culture with the help of functional yarns. From doll costumes to collaborative apparel and installations, yarn plays a hidden but essential role....

From Yarn to Trendy Icons: The Hidden Textile C...

Pop Mart isn't just selling toys—it's reshaping pop culture with the help of functional yarns. From doll costumes to collaborative apparel and installations, yarn plays a hidden but essential role....

-

Why Designers Love Photochromic Yarn: A Must-Ha...

Photochromic yarn, also known as UV color change yarn or sunlight-activated yarn, is revolutionizing the world of creative design. Beloved by fashion designers, textile artists, and hobby crafters alike, this...

Why Designers Love Photochromic Yarn: A Must-Ha...

Photochromic yarn, also known as UV color change yarn or sunlight-activated yarn, is revolutionizing the world of creative design. Beloved by fashion designers, textile artists, and hobby crafters alike, this...

-

Why Do People Think Glow in the Dark Rope Stitc...

Discover why glow in the dark rope stitch threads are gaining popularity in the world of DIY, craft, and fashion. Learn the creative and practical benefits of using these luminous...

Why Do People Think Glow in the Dark Rope Stitc...

Discover why glow in the dark rope stitch threads are gaining popularity in the world of DIY, craft, and fashion. Learn the creative and practical benefits of using these luminous...