Why Conductive Webbing is Ideal for ESD Porducts?

GokitaShare

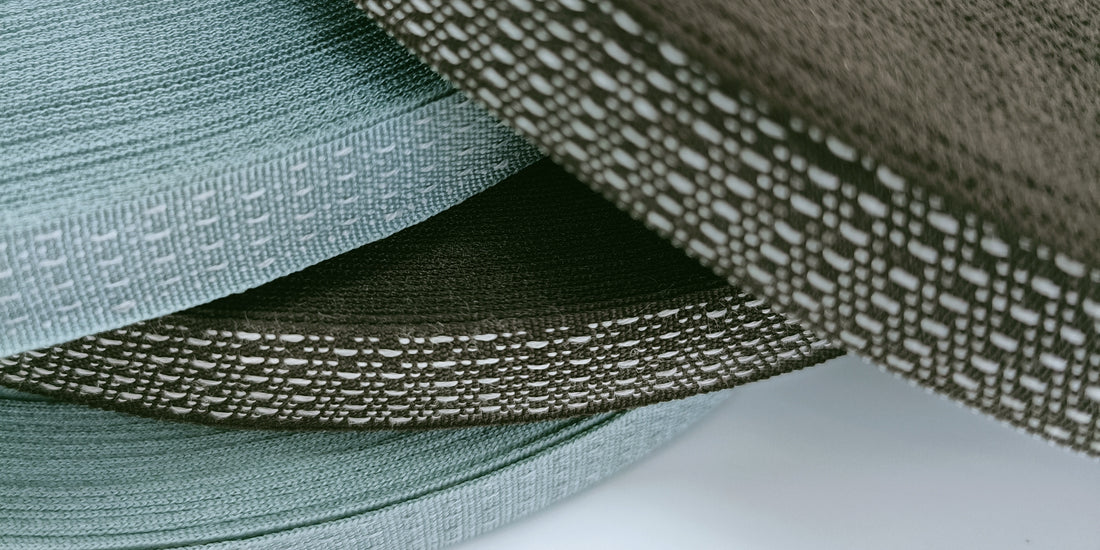

In environments where static electricity can cause significant damage, such as clean rooms and electronics manufacturing facilities, ESD products are essential. These devices prevent the build-up of static electricity by providing a continuous path to the ground. At the heart of their effectiveness is conductive webbing. This article delves into why conductive webbing is perfect for ESD products and highlights its various benefits.

1. Superior Conductivity

One of the primary reasons conductive webbing is used in ESD products is its excellent conductivity. Made from materials like stainless steel fibers woven into the webbing, it ensures efficient dissipation of static electricity. This prevents the accumulation of electrostatic charges, which can damage sensitive electronic components.

2. Durability and Longevity

Conductive webbing offers exceptional durability. The integration of stainless steel fibers makes it robust and resistant to wear and tear, even in demanding environments. This durability ensures that the ESD products remain effective over prolonged periods, providing consistent protection without frequent replacements.

3. Versatility in Applications

The versatility of conductive webbing makes it suitable for various applications beyond ESD products. Its effectiveness in preventing static build-up makes it useful in other ESD protective gear, such as wrist straps and gloves. Additionally, its durable and conductive properties are beneficial in other industrial applications where static discharge is a concern.

4. Clean Room Compatibility

In clean rooms, where maintaining a contaminant-free environment is essential, conductive webbing is particularly advantageous. It does not shed particles and can withstand rigorous cleaning protocols, ensuring that the ESD products remain functional and do not compromise the clean room standards.

5. Comfort and Flexibility

Comfort is critical for any wearable ESD protection device. Conductive webbing is designed to be flexible and comfortable, ensuring that it can be worn throughout the workday without causing discomfort. This flexibility makes it ideal for use in ESD products like Heel Grounders, which must maintain a close contact with the wearer’s shoe for optimal performance.

6. Compliance with Industry Standards

Using conductive webbing in ESD products ensures compliance with various industry standards for ESD protection. Meeting these standards is crucial for maintaining the integrity of sensitive electronic components and the overall safety of the workplace.

7. Reliability and Safety

The integration of conductive webbing into ESD products provides a reliable solution for ESD protection. By ensuring continuous grounding, it significantly reduces the risk of electrostatic discharge, which can cause costly damage to electronic components and pose safety risks in specific environments.

Conclusion

Conductive webbing is an indispensable element in the design and functionality of ESD products. Its superior conductivity, durability, comfort, and versatility make it the ideal choice for preventing electrostatic discharge in various sensitive environments. For industries that require stringent ESD protection, such as electronics manufacturing and clean room operations, conductive webbing ensures reliable and effective grounding solutions.

Dongguan Velve Thread Manufactury is committed to providing high-quality conductive webbing for ESD protection. Our products are designed to meet the highest industry standards, ensuring reliability and safety in all applications. To learn more about our conductive webbing and other ESD protection solutions, visit velve.cn.